What Is COLORBOND Steel Made Of?

COLORBOND steel is one of Australia’s most trusted building materials, used for roofing, wall cladding, fencing and a wide range of residential and commercial projects. Its reputation comes from how well it performs in the Australian climate, along with the colour finish that stays vibrant for many years. But what exactly is COLORBOND steel made from, and what gives it that reliable strength and long lasting surface?

Below is a clear and easy breakdown of the materials and layers that make up genuine COLORBOND steel.

Key Summary

- COLORBOND steel is made from a base of high quality steel.

- Several protective layers are added during manufacturing to improve corrosion resistance.

- The top coat is a painted finish that is baked on to create strong colour retention.

- The combination of steel, coatings and paint gives COLORBOND steel its durability and long lifespan.

How COLORBOND Steel Is Made

1. High Quality Steel Base

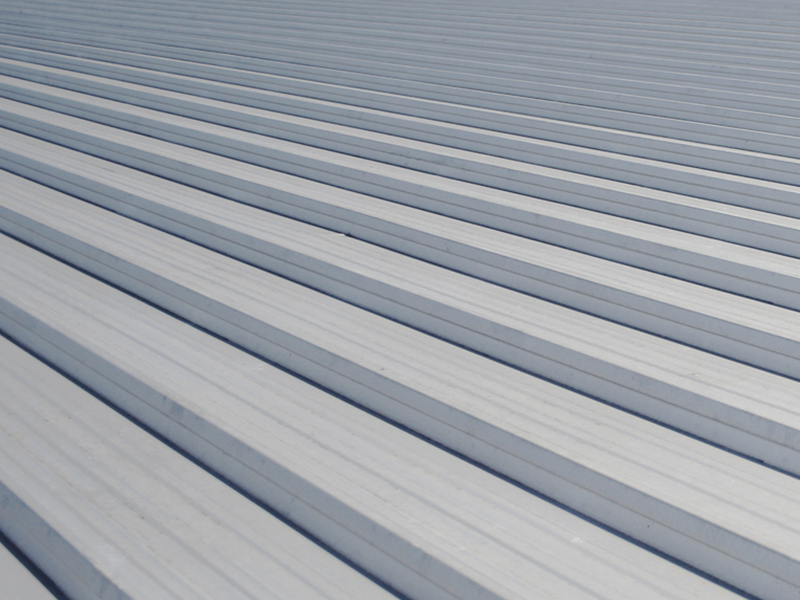

Every sheet of COLORBOND steel starts with a strong steel base. The steel provides the structural strength needed for roofing, walling and fencing. The base is manufactured to strict Australian Standards, which is why it performs reliably across a wide range of building applications.

2. Metallic Coating for Corrosion Resistance

The steel base is then coated with a metallic layer. This coating protects the steel from corrosion. The metallic layer plays a key role in helping COLORBOND products withstand harsh outdoor conditions, including heat, wind, rain and coastal environments.

3. Pre-treatment Layer

Before the paint is applied, the sheet passes through a pre-treatment stage. This helps the paint bond effectively to the metallic coating. A strong bond between the layers ensures better colour durability and a more resilient finish.

4. Primer Layer

A primer coat is added to further enhance adhesion and help protect the steel. Primer also contributes to the overall lifespan of COLORBOND steel by adding another layer between the metal and the top coat.

5. Top Coat Painted Finish

The top coat is what gives COLORBOND steel its colour. The paint is applied and then baked on, creating a tough, long lasting finish. The result is a surface that resists peeling, cracking and chipping while maintaining its colour for many years.

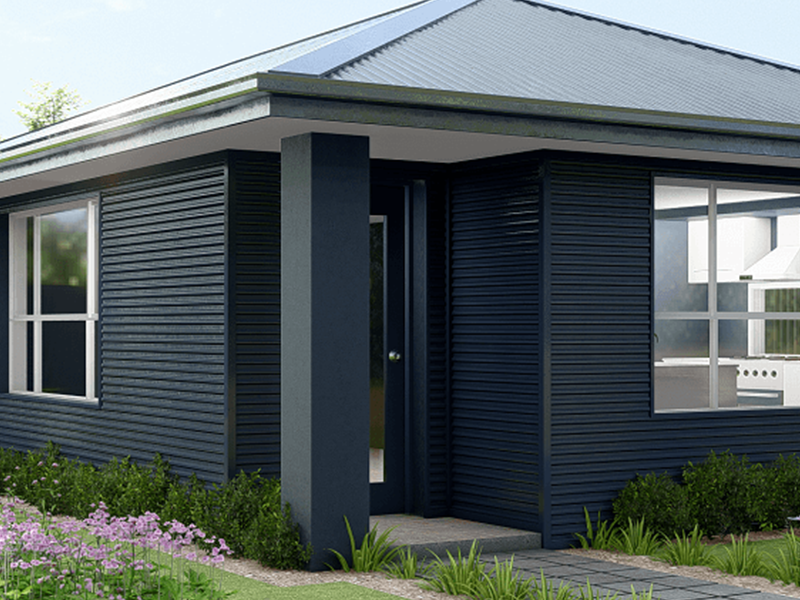

The top coat is available in a wide range of colours, which allows homeowners and builders to match roofs, walls and fencing across different parts of a project.

Why These Layers Matter

Each layer in the COLORBOND system has a specific purpose. When combined, they create a building material that is:

- durable

- corrosion resistant

- suitable for a wide range of climates

- easy to maintain

- available in a variety of colours

These benefits explain why COLORBOND steel is so widely used in Australian construction and why it remains a dependable choice for roofing and wall sheeting supplied through ClickSteel.

Where COLORBOND Steel Is Commonly Used

Genuine COLORBOND steel is used across residential, commercial and rural projects, including:

- roofing

- wall cladding

- fencing

- garage and shed construction

- patio and carport covers

- architectural feature panels

Its versatility comes from the combination of strength, appearance and weather resistance provided by the layered manufacturing process.

Choosing COLORBOND Steel for Your Project

Whether you are building a new home, upgrading a fence, adding a shed or replacing an old roof, understanding what COLORBOND steel is made from helps you appreciate why it performs so reliably.

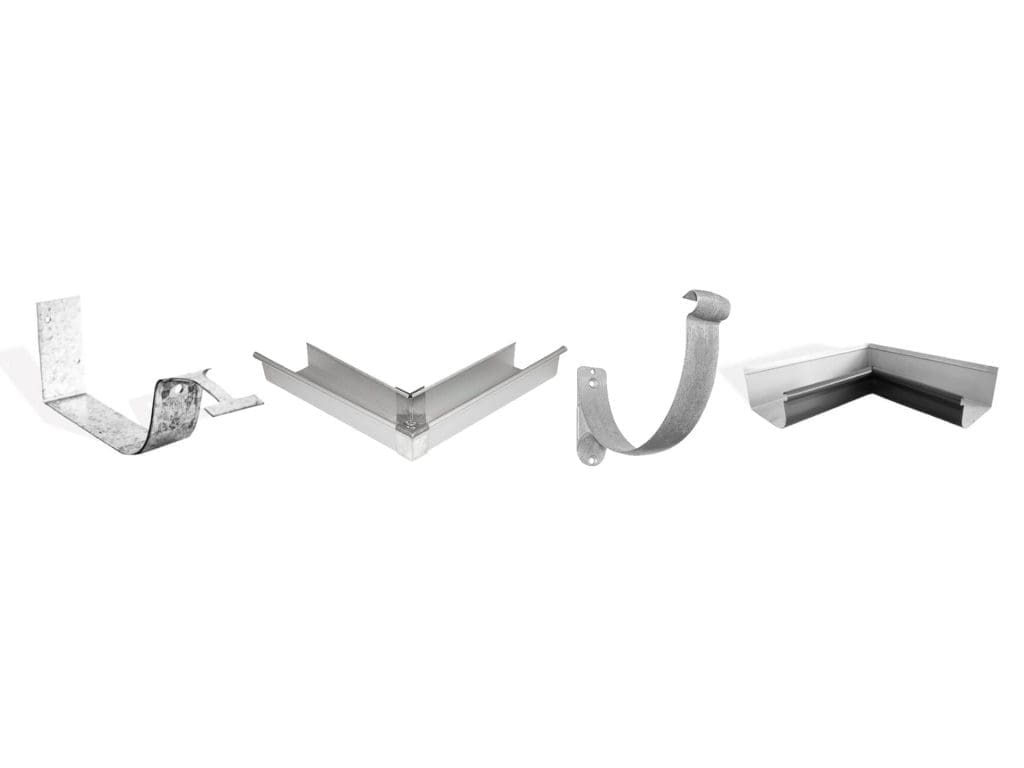

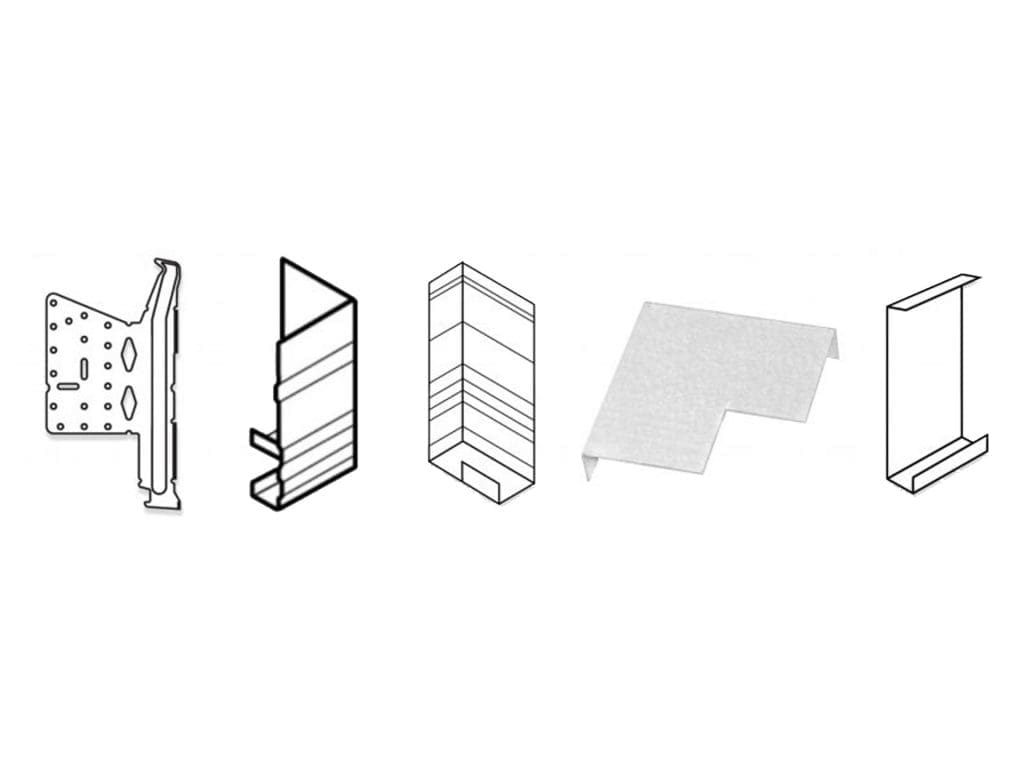

At ClickSteel, we supply genuine COLORBOND steel roofing, wall sheeting and fencing products, along with all required flashings and accessories. Explore our range to find the right profile and colour for your project